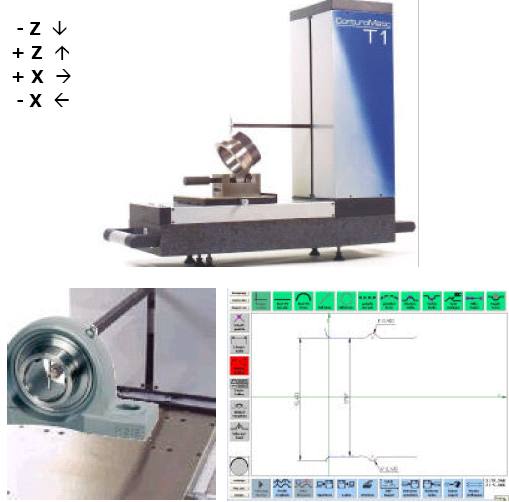

ConturoMatic T1

The 2½ D- contour measurement system

The ConturoMatic T1 offers a really versatile solution for the up and down measurement of any external or internal profile.

The T1 measuring capability is unusually large for this type of instrument. Measuring accuracy achieved is higher than other comparable contour machines, due to a combination of the very high precision horizontal travel and the unique Z axis design.

Due to the non-contact high resolution measuring scales in the X and Z axis, measurements in upper and down directions are performed with very high accuracy .

The full travel range of 250mm in the X-axis and 320 mm in the Z axis, is available for measurement use.

These high precision coordinate movements are linked to the most comprehensive software for the rapid evaluation of the traced contour in upper and down direction.

Mechanical Specification

Measuring range: 250 x 50 mm

Measuring systems: Non contact, optical, incremental in both axis.

System Resolution: 0.033 µm

Measuring speed: Automatic optimized (0.5 – 3 mm/s)

Positioning speed: Variable up to 40 mm/s

Stylii: Plug in QuadraMatic Styli with max stiffness factor. Calculated compensation for

dynamic bending effects.

Measuring tips: Standard Q.P.T. contour measuring tips with 25µm tip radius.

Measuring tip compensation: Calculated tip form compensation

Guide Bearings: Self-adjusting, maintenance free bearings.

Transmission system: Maintenance free for life.

Control System: Integrated T&S UNI-MESS, control system.

Safety Features: Drive systems limited mechanically and electrically.

Support Table: Integrated, surface 200 x 250 mm, 13 mm Y-axis adjustment. 17 Kgs load

capacity

System Accuracy: + (1,5 + L/100) µm, ?L = measuring length in mm) measured by an angular

inclined straightness standard. This system error includes the sum of all

measurement and mechanical errors.